Bag your garments and prevent them from getting dusty during storage and shipment to stores. Improve your bagging process for folded clothing pieces by implementing manual, semi-automatic or fully automatic bagging machine.

Manual

The bagging process will be completely manual. The operator must place the garment within the useful bagging area and by means of push buttons or lever, the bagging cycle will end. Then we will have to remove the already bagged garment from the machine. The main advantage of using a manual bagger is that we will use continuous plastic reels, thus avoiding having immobilized and in stock different measures of pre-cut bags. Save on raw materials and help the environment. Contact us and we will advise you with the best option.

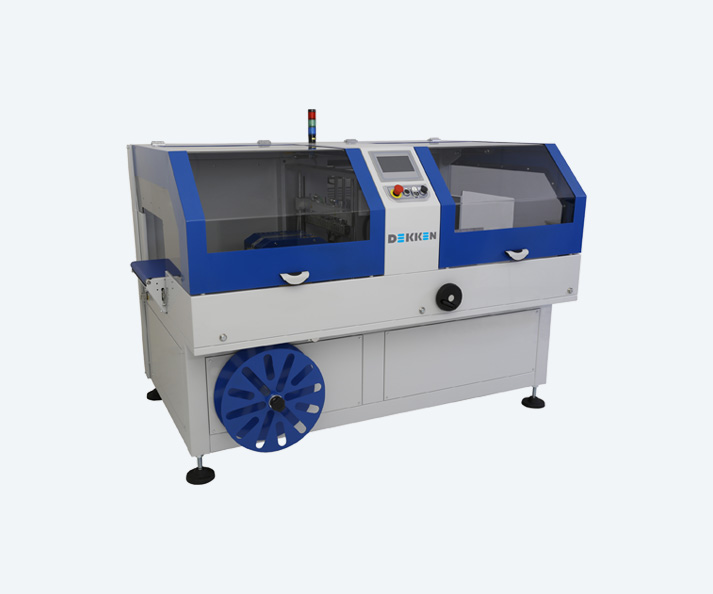

Semi-Automatic

The bagging and evacuation process will be automatic, but the garment will be fed manually. These are usually pneumatically actuated. For more information, please contact us.

Semi-Automatic

The bagging and evacuation process will be automatic, but the garment will be fed manually. These are usually pneumatically actuated. For more information, please contact us.

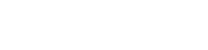

Automatic

This is the best option to be able to carry out a high number of bags in a very short time with the minimum possible human resources, providing quality bagging. The bagging machine detects the length and width of the piece to be bagged and by means of the entered parameters, it will carry out the bag to the necessary measure for each piece. The productions can go from 1,000 to 1,500 pc / h. Contact us and we will give you all the necessary information.